gas processing

Proven Gas Processing Solutions

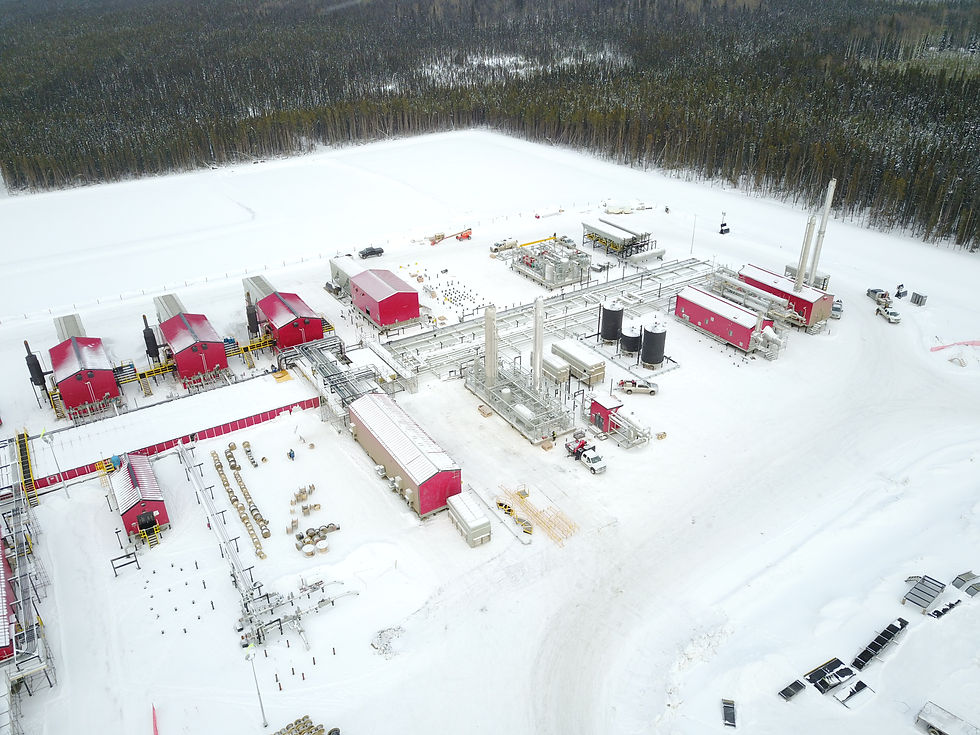

We support brownfield and greenfield developments, including complex multi-phase expansion projects. With extensive experience across the Western Canadian Sedimentary Basin, we have a long record of leading the design and execution of numerous gas processing facilities, consistently delivering projects on schedule, and within budget.

Areas of Expertise:

Design experience for facilities handling up to 450 MMSCFD of sour inlet gas, including high‑concentration sour service.

Extensive knowledge of plants, both shallow and deep cut refrigeration plants, with a proven ability to optimize NGL and C5+ recoveries. Capable of designing systems using various refrigerants, including propane, ammonia, Freon and CO2.

Experience designing deep‑cut NGL recovery facilities with and without turboexpanders.

Design capability spanning small injection pump systems to large‑scale acid gas disposal using compressors up to 5000 HP.

Experience in fractionation process, including demethanizers, deethanizers, depropanizers, and debutanizers design capability.

Expertise in gas compression ranging from small VRU units to large reciprocating compressor installations (0–5000 HP).

Experience designing refrigerated choke plant systems of various sizes.

Design experience with TEG and molecular sieve dehydration systems and JT/choke plant facilities ranging from 0 to 300 MMSCFD.

Comprehensive understanding of supporting facility infrastructure and utilities.

Proven expertise in multiple reciprocating and turbine power plants including carbon capture and waste heat recovery applications.